Plastic casting technology

We offer you sophisticated plastic potting technologies for encapsulations with particularly high pressure and adhesive strength as well as very high chemical resistance. The high sensitivity of the processes calls for continuous quality assurance in the construction of the systems and in the casting process (NCO and sample analyses). Production takes place in air-conditioned workshops.

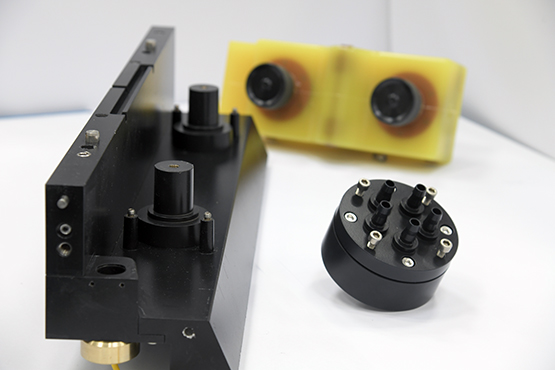

A speciality with regard to the casting process is the production of components for underwater use: The processes developed for this technology are used, for example, in the production of cables for underwater applications and similarly demanding products. We manufacture the necessary special tools and equipment for all applications ourselves to ensure flexibility and short delivery times.

We use metal bonding technology to manufacture enclosures and brackets as an alternative to screwed connections and welding techniques.

Our portfolio of services

- Ultrafine cleaning in ultrasonic baths

- Low-pressure plasma cleaning to activate the surfaces

- Application of primers (adhesion promoters) by hand spraying

- Plastic potting in various moulds, also under vacuum

- Heat treatment in drying ovens for the temperature range up to 250 °C

- Manufacture of special multi-core seawater-resistant cables for underwater operation

- Impregnation of electronic components, also under vacuum

- Pressure tests in water tanks up to max. 100 bar.

Think Differently –

Successfully Implement Solutions