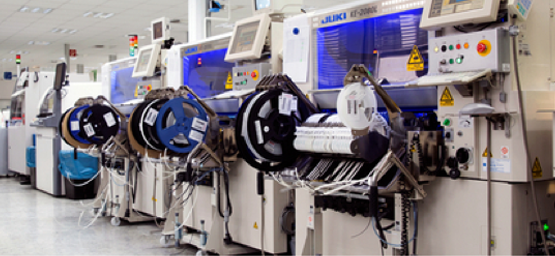

Electronic assemblies

We manufacture and test electronic PCB assemblies for you with the highest manufacturing requirements and greatest precision in SMD and THT technology.

We manufacture your products from a quantity of 1 up to large-scale production. Our delivery spectrum ranges from double-sided PCBs with a low component density to large-format 24-layer multilayers mounted on both sides, as well as from flex and rigid-flex PCBs to ultra-fine-structure PCBs on glass substrates. Fine-pitch SMDs with a lead pitch of 0.4 mm are just as much a part of our day-to-day business as BGAs with a lead pitch of 0.22 mm.

ATLAS EMS gives you the complete spectrum of electronic assembly production.

Material procurement, SMD pick-and-place and reflow soldering, THT insertion / manual soldering, functional tests and ICT as well as the protective coating of assemblies.

All processes can be carried out lead-free as well as lead-containing.

Our portfolio also includes wave and selective soldering as well as soldering in a vapour phase.

3D-SPI, 3D-AOI and X-ray inspections round off the quality assurance of our processes and thus assure the optimum quality of your assemblies.

Our portfolio of services

SMD placement:

- Solder paste printing with stencil or for small quantities or assemblies with special requirements: solder application with a high-performance solder paste dispenser

- Precision camera systems for component measurement and position correction

- The optimum soldering process for every component,

e.g. reflow for “standard” applications or vapour phase for components with complex thermal capacity profiles.

Functional test:

- Automated and semi-automated functional test

- Test system development according to customer requirements

- Freely expandable test system according to customer requirements

- Obsolescence management → maintaining testability over 40 years

- Own software environment, adaptable to customer requirements → optimized for troubleshooting

- Extensive experience with complex tests and verifications → also for the system testing

- Competent advice on testing strategy and on the optimization of existing testing processes

Assembly marking:

- Laser marking of metal signs, foil labels and front panels incl. logos and consecutive serial numbers, also bar code and Data Matrix

Other technologies:

- THT (through-hole technology) placement

- Double wave soldering unit 400 mm wide with nitrogen tunnel

- Partial soldering

- Pressing in complex connector strips

- Mounting of power supply units

- Assembly coating

- Programming of electronic components

- Cleaning of assemblies according to MIL standard

- 3D-SPI testing, 3D-AOI inspection for optimum process monitoring

- Solder joint inspection, also with X-ray systems

- Flying probe test without needle bed adapter

- Standard in-circuit test with up to 1152 node points, up to 50 MHz

- Combined in-circuit/functional test via needle bed adapter or connector strip

Think Differently –

Successfully Implement Solutions